About CFI

CFI is a privately-held filler supplier for manufacturing industries such as rubber, silicone, plastics, and coatings

Established in 1987 with plant locations in West Virginia and Virginia, we drive more profitable innovation for the global industrial leaders we serve with sustainable consistency in quality products, source stability, logistics, and service. We are certified to ISO 9001:2015 standards with an on-site ISO-certified lab for product monitoring and analysis and work with ACE Products and Consulting for research and development initiatives – to ensure top-quality products, optimal process, and overall formula improvements for our customers.

In markets where product consistency and delivery require precision, CFI and Austin Black 325 deliver.

Our signature product – Austin Black 325

Our signature product–Austin Black 325–is one of the most cost-effective and versatile organic fillers available, compared to other clay, talc, and calcium carbonate fillers. It can reduce product weight and improve profitability while increasing processability and flowability.

Unlike the Carbon Black manufacturing process, our low CO2 emissions process ensures that it is both eco-friendly and cost-effective. Our consistent, high-quality product and highly attentive customer support position manufacturers for success and inspire long-standing collaborations.

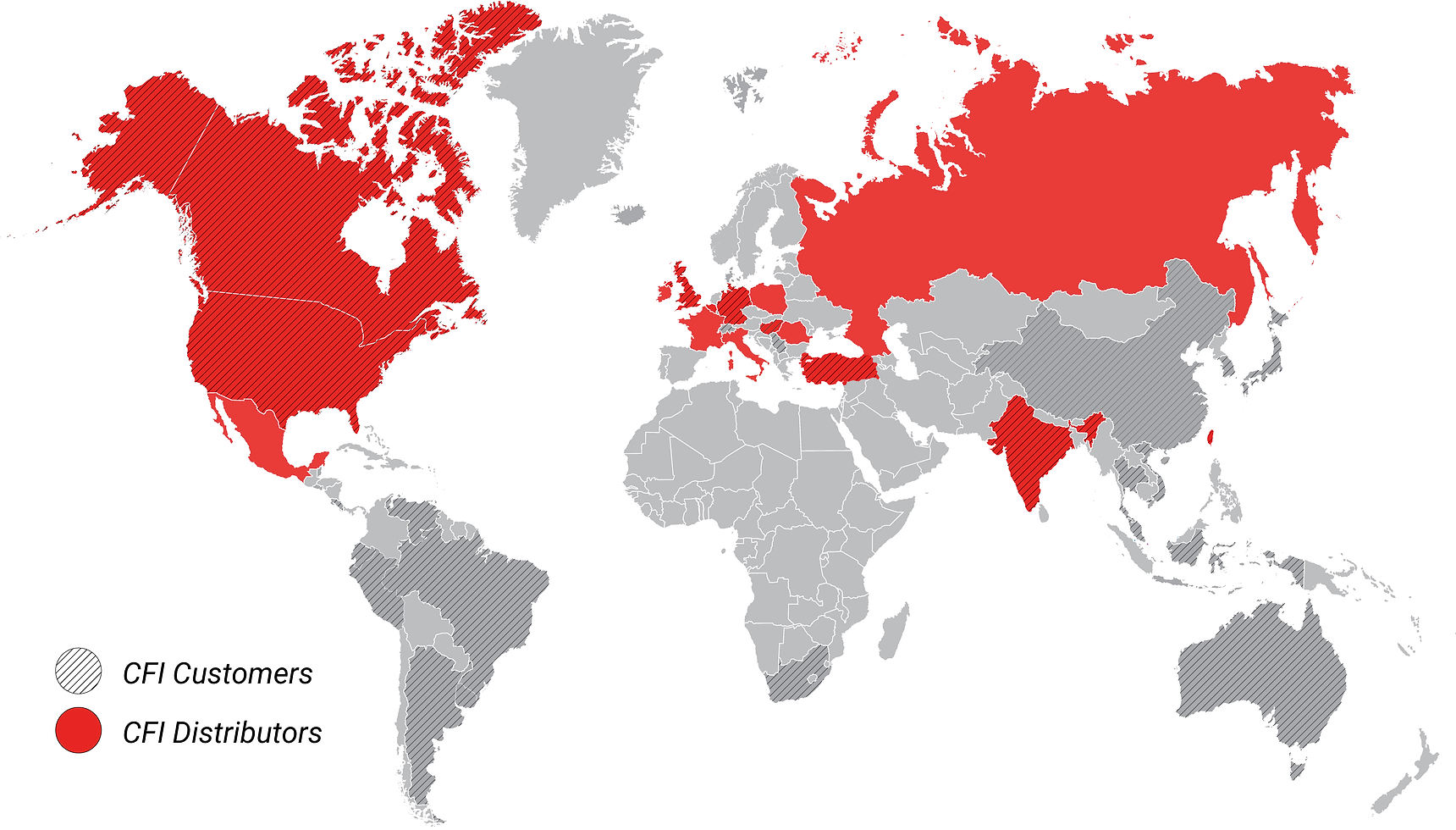

With three US plants for processing, eight local sources for raw materials, our on-site lab, and a third-party lab, reliability is ensured. Likewise, on the delivery and logistics side of the business, our 30 years of experience and complete control of operations help us to provide exceptional services and on-time global delivery.

All of this adds up to high marks from customers and partners for products and services. In fact, 94% of customers surveyed rated service from CFI as above average or excellent.

Helping each customer improve formulas, end products, and processes

At CFI, our mission is to help each customer improve formulas, end products, and processes in order to achieve more profitable innovation. While being fully dedicated to the daily needs and successes of our customers, we also proudly commit to a culture of manufacturing progress that spans across multiple industries as evident in our research and development initiatives.

For these reasons and more, we are a great manufacturing partner and provide a great place to work. If you are interested in joining us, please contact us to tell us more about your goals.

Environmental Practices

Our processes and products are responsibly engineered for improved resource productivity

By setting environmentally sound goals and achieving them at CFI, we can help your company achieve its environmental manufacturing goals. We produce very low emissions from industrial processes and only an insignificant amount from vehicle traffic.

Our signature product Austin Black 325 is produced by taking bituminous coal–a naturally occurring raw material–through a specialty milling process without added chemicals. The result is a more CO2-neutral product than a regular Carbon Black which is made with burning oil or gas.

To support our on-going commitment to sustainability practices, we work with Ecovadis for regular environmental impact assessment.

Customer Focused

Quick replies

Leadership

Our people are knowledgeable and committed to supporting your business

Chris Cook, CPA

Accountant

Alese Jewell

Inside Sales Representative

Tim Toney

Tams Plant Manager

Chris Jarrell

President

Brian Higginbotham

Director of Plant Management/Purchasing

Reviews and Ratings

Our Experience Is Your Advantage

Hear what our incredible customers have to say!

"Alese Jewell is very helpful and I appreciate how quickly she responds to emails, etc."

Chemical Distributor

"We're very happy with the Austin Black we purchase from CFI. It's become the main filler we use in one of our potting sealants. We've found that Austin Black can be used at higher concentrations than standard carbon blacks without significantly increasing the viscosity of the sealant. Customer service has also been great. Cyndi Foley has been our primary CFI contact. She has been excellent to work with, and is very helpful and responsive."

J.C. with Luna Labs

"Great team at CFI, we appreciate everything you guys do."

S.D. with Carlisle Construction Materials

"Good service and performance, please maintain this achievement."

E.P. with Sumitomo Rubber

"Good service, fast response, please keep it up"

Rubber Manufacturers

“With Austin Black 325, we achieved better air retention and compression set.”

Raw Materials Supplier

"With Austin Black 325, get increased fill without increased SG."

Rubber Products Manufacturer

“Our results included improved efficiency rating in manufacturing.”

Raw Materials Supplier

“With Austin Black 325, we see consistent quality, higher purity. And we improve compression set in O-ring application.”

Raw Materials Supplier