Article Summary

This guide delves into the necessary materials known as pvc additives. These components convert basic Polyvinyl Chloride (PVC) into the adaptable material found in countless industrial applications. The discussion covers:

- Why pvc additives are fundamental for PVC processing and final product behavior.

- Major types of pvc additives, such as stabilizers, plasticizers, and fillers, with explanations of their roles.

- The specific contribution of fillers as pvc additives to cost control and property modification.

- Advantages offered by advanced pvc additives, like CFI Carbon Products’ Austin Black 325 mineral black, focusing on weight reduction and easier processing.

- Sustainability aspects related to pvc additives and the push for environmentally sound choices.

- Criteria manufacturers use to select the most effective pvc additives for specific needs.

- Examples where optimized PVC formulas, achieved through correct pvc additive selection, yield better results.

The Necessity of PVC Additives in Polymer Formulation

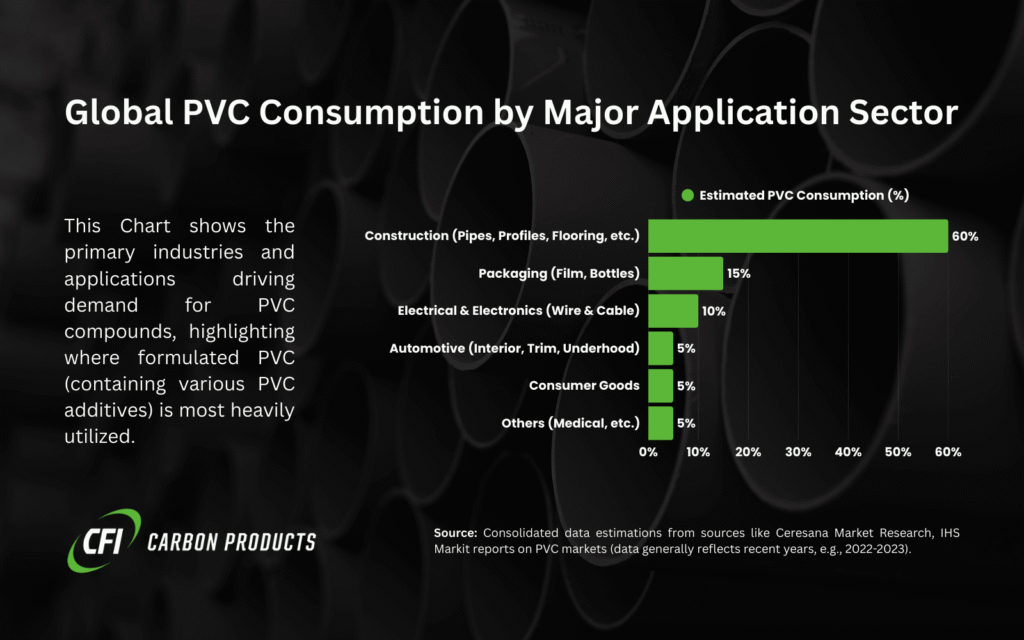

Polyvinyl Chloride, or PVC, ranks among the world’s most used thermoplastic polymers. Its natural chemical resistance and durability offer significant advantages. Yet, raw PVC presents challenges. It is inherently brittle and degrades quickly when heated for standard processes like extrusion or molding, releasing corrosive gases before it flows properly. This instability means processors cannot use PVC effectively without modification.

The solution involves pvc additives. These are specific chemical substances combined with PVC resin. Their purpose is to overcome the polymer’s natural shortcomings and introduce desired traits into the final product. Without the correct pvc additives, the extensive use of PVC in items from rigid pipes to flexible hoses would be impossible. Successful manufacturing requires detailed knowledge of pvc additives to meet performance standards, budget constraints, and environmental targets. The following table clarifies the fundamental need for these materials.

| Challenge with Raw PVC | Solution Provided by PVC Additives | Consequence Without Additives |

| Thermal Instability (Degrades on heating) | Stabilizers prevent breakdown during processing. | Material decomposes, releases HCl gas. |

| Brittleness (Easily broken) | Impact modifiers increase toughness; Plasticizers add flexibility. | Limited applications, prone to failure. |

| Processing Difficulty (Poor flow) | Lubricants reduce friction; Processing aids improve melt quality. | Inefficient production, poor surface finish. |

| UV Sensitivity (Degrades outdoors) | UV stabilizers absorb or dissipate harmful radiation. | Discoloration, reduced lifespan. |

| High Material Cost (Relative to alternatives) | Fillers replace a portion of the PVC resin. | Higher overall product cost. |

Understanding the Primary Categories of PVC Additives

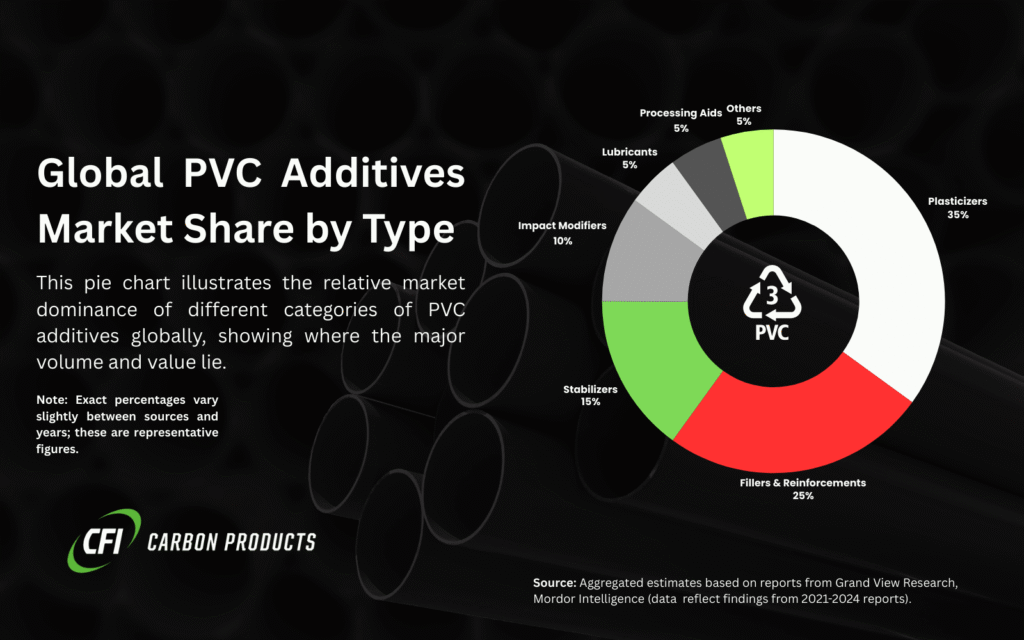

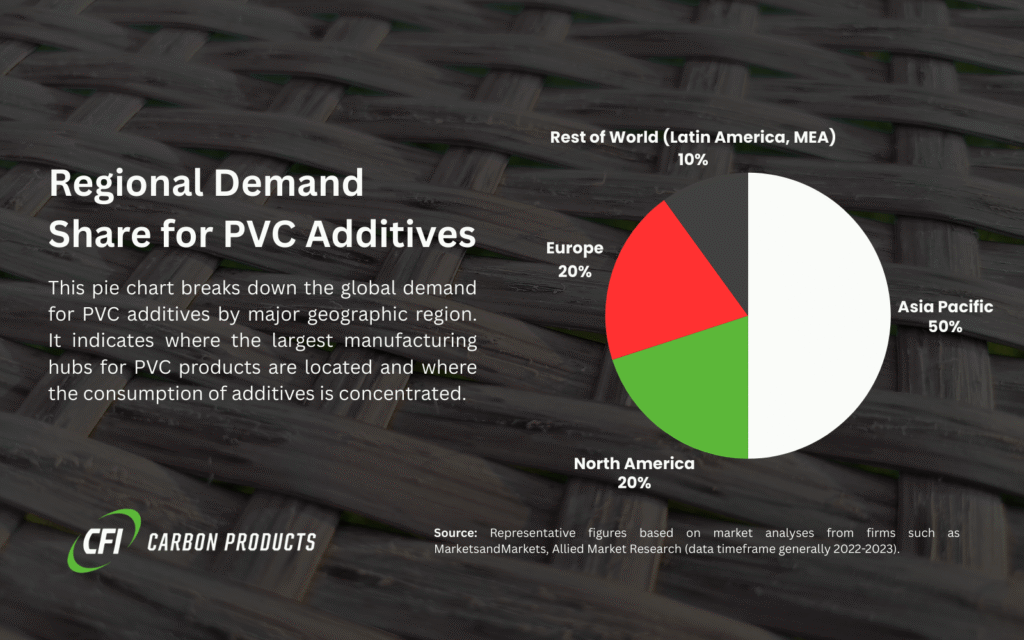

The formulation of PVC involves a careful selection from various pvc additives. Each type targets specific properties or processing behaviors. Manufacturers must recognize these categories to formulate compounds effectively. Below is a breakdown of the major types and their core functions.

| Additive Category | Core Function | Examples & Notes | Relevance to PVC |

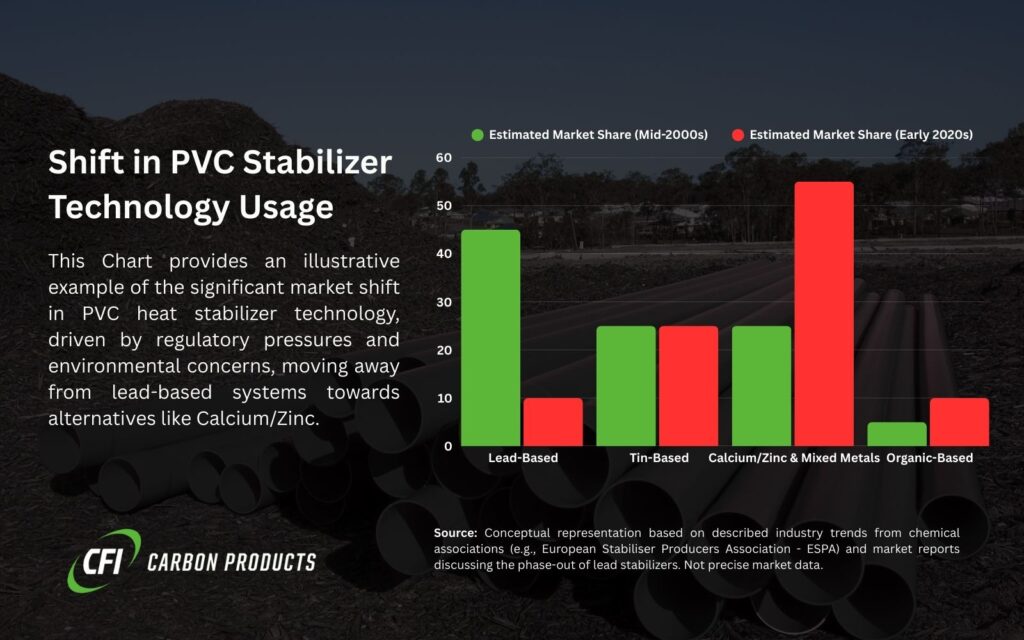

| Stabilizers | Protect PVC from heat damage during processing and degradation from environmental factors (heat, light). | Tin, Calcium/Zinc, Mixed Metal systems. Lead systems are largely phased out. | Essential for preventing decomposition. |

| Plasticizers | Impart flexibility, softness. Lower the temperature needed for processing. | Various Phthalates, Adipates, Trimellitates, newer bio-based options. Used primarily for flexible PVC items. | Key for flexible applications (wire, film). |

| Lubricants | Reduce friction within the PVC melt (internal) and between melt and machinery (external). | Stearates, waxes, fatty acid esters. | Critical for smooth processing, output rate. |

| Processing Aids | Enhance melt uniformity, strength, and surface appearance. Help PVC particles fuse together. | Typically acrylic copolymers. | Improves quality and consistency. |

| Impact Modifiers | Boost resistance to fracture from impact, crucial for rigid items, especially at low temperatures. | Acrylics, MBS (Methacrylate-Butadiene-Styrene), CPE (Chlorinated Polyethylene). | Essential for pipes, profiles, housings. |

| Fillers | Primarily reduce cost; can also increase stiffness, control density, improve electrical properties. | Calcium Carbonate (ground/precipitated), Talc, Clay, Mineral Blacks like Austin Black 325. | Widespread use for cost and performance. |

| Pigments/Colorants | Provide color. | Titanium Dioxide (white), Carbon Black (black), organics. | Aesthetic and functional identification. |

| Flame Retardants | Decrease flammability; required for specific building codes and electrical standards. | Antimony compounds, phosphate esters, halogenated materials (usage varies). | Safety in construction, electrical gear. |

| Biocides | Inhibit fungal or bacterial growth on the PVC surface. | Specialized organic compounds. | For flooring, wallcoverings, humid areas. |

| UV Stabilizers | Protect against UV radiation damage, key for outdoor lifespan. | Benzotriazoles, HALS. Integral for exterior applications. Find more on UV stabilizer additive properties. | Durability for outdoor products. |

Choosing the right mix from this extensive plastic additives list requires expertise. Interactions between different pvc additives are common – some enhance each other, while others conflict. A well-designed formula achieves synergy for the target performance profile. General familiarity with plastic additives and broader polymer additives provides useful context.

The Functional Role of Fillers as PVC Additives

Fillers represent a major category of pvc additives, historically used mainly to lower the cost per pound of PVC compound. By substituting less expensive material for PVC resin, overall costs decrease. Today, fillers often provide specific functionalities beyond cost reduction. These functional fillers are chosen to improve physical properties or processing behavior.

Common traditional fillers are detailed below:

| Traditional Filler | Key Characteristics | Typical Impact on PVC Properties | Primary Reason for Use |

| Calcium Carbonate | Low cost, abundant, various particle sizes available. | Increases stiffness, can lower impact strength if coarse. | Cost Reduction |

| Talc | Platy structure, relatively inert. | Increases stiffness, improves heat deflection temperature. | Stiffness, HDT |

| Clay (Kaolin) | Fine particles, different grades. | Can improve electrical insulation, barrier properties. | Electrical, Barrier |

While effective for cost and certain properties, traditional mineral fillers usually increase the compound’s specific gravity, making products heavier. High loadings needed for significant savings might compromise toughness or flexibility.

This situation creates opportunities for advanced pvc additives like CFI Carbon Products’ Austin Black 325 mineral black. Sourced from bituminous coal, this finely ground powder acts differently than standard fillers. A key distinction is its lower specific gravity. This feature allows Austin Black 325 to function as a pvc additive that reduces final product weight while often helping other properties. It offers a different approach compared to typical plastic fillers or plastic filler material. Its origin distinguishes it clearly from conventional carbon black – understand the contrast between black vs carbon black.

How PVC Additives Deliver Targeted Performance

The precise application dictates which performance aspects are most important, guiding the selection of pvc additives. Manufacturers use these materials strategically to meet demanding specifications.

Here’s how specific pvc additives contribute to key performance areas:

| Performance Target | Key PVC Additive Types Used | How They Contribute | Example Applications | Relevant CFI Insights |

| Mechanical Strength | Impact Modifiers, Reinforcing Fillers | Modifiers absorb impact energy; Fillers increase stiffness and rigidity. | Pipes, Profiles, Housings | Techniques for plastic reinforcement often rely on filler choice. |

| Processability | Lubricants, Processing Aids, Certain Fillers | Reduce friction, improve melt flow/uniformity, prevent sticking/degradation. | Extrusion, Injection Molding | Austin Black 325 can enhance flow. Efficient [polymer processing additives] reduce energy use. |

| Durability | Thermal Stabilizers, UV Stabilizers | Prevent breakdown from heat, light, and weathering. | Outdoor Profiles, Roofing, Siding | Importance similar to materials used in rubber roofing material designs. |

| Cost-Effectiveness | Fillers | Replace more expensive PVC resin. | Virtually All Applications | Low-density fillers like Austin Black 325 impact volume cost, contributing to overall profitability. Compare filler costs to base resin and alternatives like carbon black (carbon black pricing). |

| Weight Reduction | Low-Density Fillers | Decrease the overall specific gravity of the compound. | Automotive, Transportation | Austin Black 325 (SG ≈ 1.3) is lighter than many fillers (CaCO3 ≈ 2.7) or carbon black (≈ 1.8 – see carbon black density). |

| Color | Pigments, Certain Fillers | Impart desired color. | Visible Parts, Coding | Austin Black 325 provides black color; function differs from high-tint furnace black often used in carbon black for plastics for deep black. |

| Electrical Properties | Specific Fillers, Some Stabilizers | Modify conductivity or insulation properties. | Wire & Cable Insulation | Choice depends on whether conductivity (is carbon conductive?, resistivity of carbon) or insulation (is carbon a good insulator?) is needed. |

| Flame Resistance | Flame Retardants | Reduce flammability to meet safety codes. | Construction, Electrical | Specific pvc additives required by standards. |

Specialty needs, like controlled flow in coatings rheological additive, specific surface effects paint additive for cabinets, additives for wood coatings, or unique chemistries polyurethane additives, additives for paints, may involve less common or highly specialized industrial additives and specialty additives. Many principles overlap with requirements for coating additives, adhesive additives, and resin additives.

Sustainability and Environmental Factors in PVC Additives

The environmental impact of materials is a growing concern for manufacturers and consumers. The pvc additives industry is responding to demands for more sustainable solutions. Past concerns involved heavy metal stabilizers (lead, cadmium) and certain phthalate plasticizers, leading to restrictions and replacement efforts.

Current focus areas for sustainability include:

| Sustainability Aspect | Description & Relevance to PVC Additives | Example Trends or Solutions |

| Material Chemistry | Shift away from additives with known health or environmental risks. | Transition to Calcium/Zinc or organic-based stabilizers; Use of non-phthalate or bio-based plasticizers. |

| Resource Efficiency | Utilizing readily available resources; Additives that enable use of recycled PVC content or lightweighting. | Austin Black 325 uses abundant coal source; Low-density fillers reduce material needed per part. |

| Energy Consumption | Additives that improve processing efficiency require less energy during manufacturing. | Efficient lubricants, processing aids; Fillers that lower melt viscosity. |

| Supplier Responsibility | Choosing suppliers with documented environmental management systems and transparent practices. | Suppliers providing CO2 footprint data; ISO 14001 certification. |

| End-of-Life | Formulations designed to be more readily recyclable or manageable at the end of the product’s life. | Research into additive compatibility for recycling streams. |

CFI Carbon Products addresses sustainability directly through its production of Austin Black 325. Manufactured from bituminous coal via a process with lower associated CO2 emissions than traditional furnace carbon black production, it offers an environmentally conscious choice among pvc additives. Its function as a low-density filler also supports lightweighting strategies, indirectly benefiting sustainability through reduced material use and potential transport savings. This approach aligns with seeking eco-friendly rubber alternatives concepts, applying them within the broader pvc additives context.

Introducing Austin Black 325: An Advanced Mineral Black PVC Additive

Austin Black 325 offers properties that distinguish it from many common pvc additives, especially conventional fillers and standard carbon blacks. It is produced by grinding high-quality bituminous coal, not through combustion like furnace blacks. This unique source and process yield a mineral black with valuable characteristics for PVC formulators. Its role is less about extreme reinforcement or tint strength (key functions outlined in what does carbon black do?) and more focused on cost-effective functional modification.

The table below summarizes the key attributes and benefits of using Austin Black 325 as a pvc additive:

| Property/Attribute | Description | Benefit in PVC Formulations | Comparison Point |

| Source Material | High-quality, low-volatile bituminous coal. | Consistent quality, domestic US source (WV, VA). | Differs from petroleum residues used for furnace black or mined minerals like CaCO3. |

| Production Process | Specialized grinding process. | Lower associated CO2 emissions than furnace black production. | Significantly different energy profile and emission factor compared to high-temperature combustion processes. |

| Specific Gravity | Low (approx. 1.3 g/cm³). | Enables compound weight reduction (lightweighting), higher volume yield per unit weight. | Lower than CaCO3 (≈ 2.7), Talc (≈ 2.7-2.8), and typical furnace carbon blacks (≈ 1.8). |

| Processability Impact | Often improves melt flow, reduces viscosity compared to some fillers. | Easier processing, potential for lower energy use or faster cycles. | Acts as a processing aid in some systems, unlike some mineral fillers that can increase viscosity significantly. |

| Cost Dynamics | Competitive pricing, significant impact through low density (volume cost). | Potential for overall formulation cost savings when replacing denser, more expensive components by volume. | Cost-per-pound vs. cost-per-volume calculation is critical compared to other fillers. |

| Particle Characteristics | Fine, relatively uniform particle size distribution. | Good dispersion within the PVC matrix, consistent properties, smooth surface finish. | Structure differs from highly structured furnace blacks (carbon black structure). Different grades exist, similar concept to carbon black grades. |

| Color Contribution | Provides black coloration. | Suitable for applications needing black color where high tint strength is not the primary goal. | Tinting strength lower than high-color furnace blacks used primarily for deep jetness. |

By leveraging these properties, Austin Black 325 serves as a versatile pvc additive. It allows manufacturers in the plastics industry to achieve performance goals that might be difficult or more expensive with traditional approaches alone. Its benefits sometimes parallel those sought with carbon black for rubber or carbon black for coatings, namely property modification and cost control, but achieved through different material characteristics.

Optimize Your PVC Formulations with Austin Black 325

The right choice of pvc additives is fundamental to creating competitive PVC products. If your goals include lower product weight, improved manufacturing efficiency, effective cost management, and incorporating materials with a better environmental story, Austin Black 325 mineral black deserves evaluation. Its unique combination of low density and processing benefits provides a compelling alternative to conventional fillers and additives.

Discover how Austin Black 325 can enhance your PVC compounds. Visit the product page for detailed specifications and case studies. Let CFI Carbon Products help you innovate.

Explore Austin Black 325 Technical Data

For comprehensive support, including formulation guidance and technical documentation, CFI provides extensive resources. Our team, though lean (fewer than 40 employees), offers agile and personalized support backed by decades of experience since 1987. Visit our main Services page or the complete Resources Index for more information.

Criteria for Selecting PVC Additives

Choosing the most suitable pvc additives requires a systematic approach. Manufacturers must weigh several critical factors to ensure the final compound meets all performance, cost, and regulatory demands.

| Selection Factor | Key Questions for Manufacturers | Importance |

| Performance Needs | What mechanical, thermal, electrical, and aesthetic properties are required for the application? | Directly determines the types and loading levels of essential pvc additives. |

| Processing Method | How will the PVC compound be processed (extrusion, molding, etc.)? What are the machine limits? | Dictates required flow characteristics, thermal stability window, need for lubricants/aids. |

| Regulatory Landscape | What rules (REACH, RoHS, FDA, NSF, regional laws) apply to the end product and its materials? | Non-negotiable for market access; restricts the use of certain pvc additives. |

| Cost Structure | What is the target cost for the final compound? How does each additive impact the total price? | Balances performance with economic viability. Requires volume cost analysis for fillers. |

| Sustainability Policy | Does the company have targets for recycled content, reduced carbon footprint, or greener materials? | Guides selection towards environmentally preferable pvc additives and responsible suppliers. |

| Supplier Attributes | Is the supplier reliable? Do they offer consistent quality, technical support, secure supply? | Critical for operational stability and quality control. CFI emphasizes its US base and logistics. |

Making the right choices often involves testing and iterating formulations, leveraging supplier expertise like that offered by CFI for its pvc additives.

Key Takeaways: Mastering PVC Additives

| Takeaway Topic | Core Message | Implication for Manufacturers |

| PVC Additives are Mandatory | Raw PVC is unusable for most applications without modification. | Investment in correct pvc additive selection and formulation is essential for product success. |

| Function Dictates Choice | Each additive type performs specific tasks; careful selection is needed to balance properties. | Understanding the role of stabilizers, fillers, modifiers, etc., is key to targeted formulation. |

| Fillers Offer More Than Savings | Modern fillers act as functional pvc additives, influencing density, processing, and mechanicals. | Evaluate fillers based on total contribution (cost, performance, weight) not just price per pound. |

| Sustainability is Key Driver | Environmental considerations increasingly shape pvc additive development and selection. | Seek suppliers and materials with verifiable sustainability benefits (e.g., lower CO2, safer chemistry). |

| Innovation Creates Opportunity | Advanced materials like Austin Black 325 provide unique advantages (low density, process aid) over traditional options. | Stay informed about new pvc additives to gain competitive advantages in performance or cost. |

| Holistic Selection Process | Optimal pvc additive choice considers performance, processing, cost, regulation, and sustainability goals together. | Requires cross-functional collaboration (R&D, Production, Purchasing) and strong supplier partners. |

Effective use of pvc additives underpins the vast utility of PVC. By understanding their functions and exploring advanced options like Austin Black 325, manufacturers can continue to innovate and produce high-performing, cost-effective, and more sustainable products.