Austin Black 325

Fill More Molds with Fewer Pounds of Material

Product advantages

Low Specific

Gravity

Increased Processability

Low Carbon Emissions

Increased Profitability

About Austin Black 325

Produced from high-quality, low-volatile, bituminous coal, Austin Black 325 is a dry, finely divided powder with low specific gravity.

Known for its consistent, versatile, and formula-improving attributes, it can reduce end-product weight and increase profit margins.

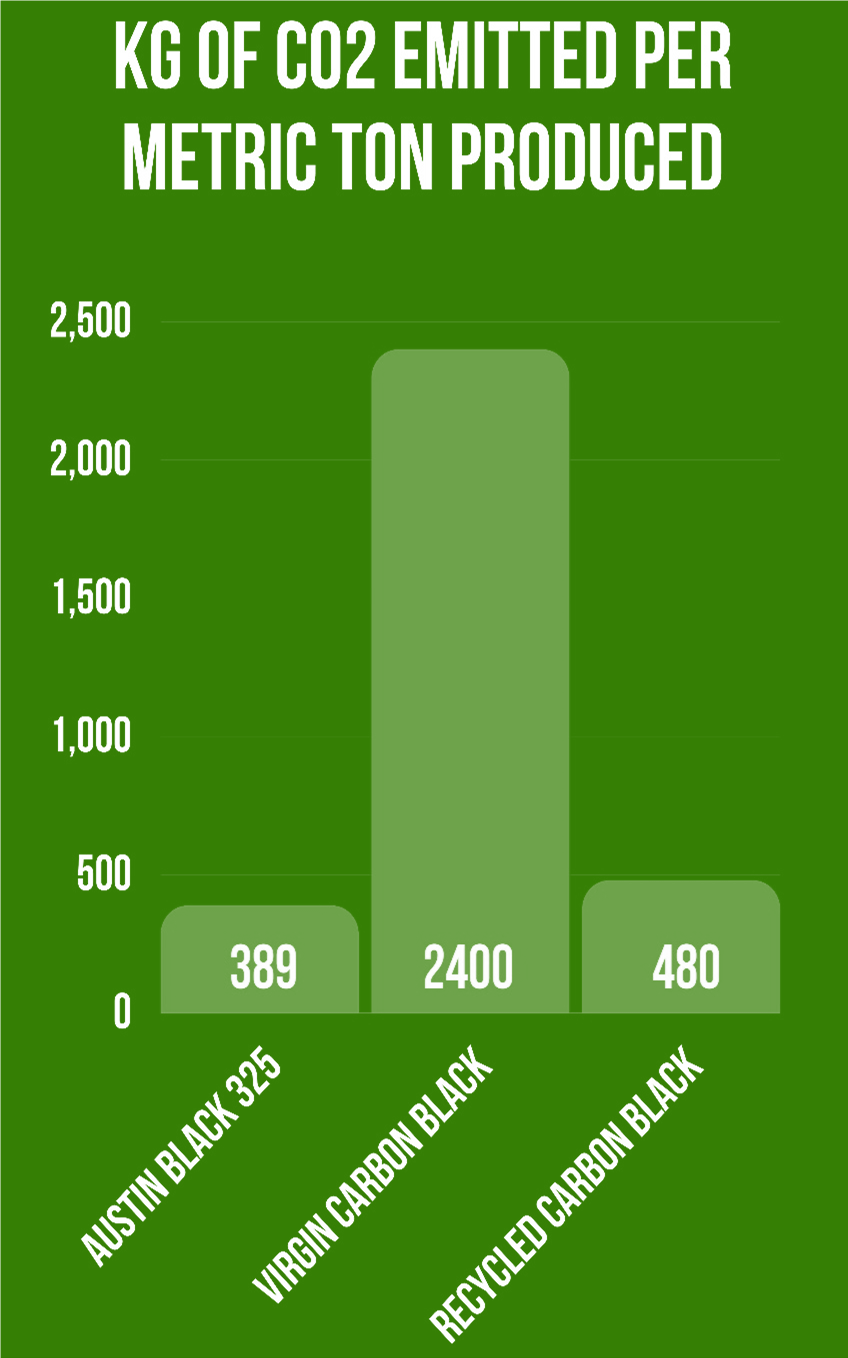

Austin Black 325 is a low-emission filler, emitting less CO2 than both virgin and recycled Carbon Blacks*.

*Source G3C Technologies

Compared to Other Clay, Talc, and Calcium Carbonate Fillers, Austin Black 325 is One of the Most Cost-Effective and Versatile Organic Fillers Available.

Formula Improvements

Reported by customers include:

- Reduced end-product weight

- Increased processability

- Greater flowability

- Improved compression

- Higher insulating properties

- Long-term durability

- Odor-scavenging attributes

- Reduced air permeation & improved air retention

- Improved efficiencies in manufacturing

- Helped resolve air entrapment issues in various compounds

- Additional loading with cost reduction

Why choose us?

Sample Applications

- Tires (All Types)

- Automotive Seals, Hoses, and Belts

- Plastics

- Conveyor Belts

- Paints and Coatings

- Commercial Roofing (EPDM, TPO)

- Sealants and Caulks

Sample Cost Savings

- Reported by customers include:

- Lower cost per batch.

- Lower cost and reduced IIR rubber usage.

75% of customers surveyed reported cost savings as a benefit of using Austin Black 325.

- Some reported saving up to 25%.

More Resources

Download the Technical Data Sheet

Download the Safety Data Sheet

View Packaging Options

Is Austin Black 325 the same thing as Carbon Black?

How does Austin Black 325 stack up against other fillers?

What makes Austin Black 325 more cost effective than other fillers?

How can Austin Black 325 be carbon neutral?

Frequently Asked Questions

What is Austin Black 325 used for?

Austin Black 325 is commonly used as a cost-effective pigment and filler in the plastics, rubber, coatings, and automotive parts. It improves UV resistance and provides a consistent with black color.

What is Austin Black and how is it produced?

Austin Black is a finely milled, low-volatility powder made from high-quality bituminous coal. Its structure and sourcing make it an effective pigment and filler across multiple applications.

Is Austin Black safe to use in manufacturing processes?

Yes, it’s a naturally occurring mineral that is considered safe for industrial applications when used according to standard handling guidelines. Always refer to the MSDS for best practices.

How does Austin Black improve rubber compounding?

When combined with HAF or FEF carbon blacks, it enhances physical properties while significantly reducing costs. It also acts as a processing aid, improving dispersion and reducing bubbles and blisters in the final compound.

How does it support electrical performance in materials?

Austin Black 325 improves dielectric properties, especially in rubber insulation compounds that are exposed to moisture, improving electrical stability over time.

What specific performance benefits does Austin Black 325 offer?

It boasts excellent dielectric (insulation) properties, UV and chemical resistance, and low moisture absorption. It also aids in air release and moisture control, improving overall compound stability.

How does Austin Black compare to traditional carbon black?

While not as intense as traditional carbon black, we offers excellent dispersion, lower specific gravity, and affordability—making it ideal for non-critical coloration and reinforcement.

Can Austin Black improve UV stability in plastics?

Yes, it contributes to UV stability in plastic and rubber products, helping extend their lifespan in outdoor or sunlight-exposed environments.

Is suitable for environmentally conscious products?

Absolutely. It’s a naturally mined mineral product with a lower carbon footprint than synthetic alternatives, making it a strong choice for sustainable formulations.